ABOUT MIRADUR

At MIRADUR Precision Machining LLC, we specialize in providing high-precision CNC machining and manufacturing solutions to industries such as automotive, aerospace, industrial machinery, and medical sectors. Our commitment to excellence extends to our customer service, where we strive to offer expert advice, timely support, and a seamless experience.

We value customer satisfaction and aim to build lasting relationships based on trust and mutual success. Our state-of-the-art manufacturing facility in Kunshan, China, along with our growing presence in the United States, enables us to deliver precision-engineered components to top global manufacturers.

OUR SERVICES

Explore our comprehensive range of high-precision CNC machining and manufacturing services designed to enhance your projects and deliver exceptional performance. From high-precision component customization to carbon fiber and polymer component manufacturing, we have everything you need for reliable and scalable CNC solutions.

Advanced CNC Machining Capabilities

Cutting-Edge Capabilities

Our facility is equipped with state-of-the-art CNC machines, including:

✔ 5-axis CNC machining for complex geometries and intricate details.

✔ High-speed milling and turning for rapid production with tight tolerances.

✔ Multi-axis machining centers that allow simultaneous movement, reducing production time and increasing precision.

✔ Grinding, EDM (Electrical Discharge Machining), and laser cutting for specialized applications.

We specialize in machining high-precision components with tolerances as tight as ±0.005mm, ensuring reliability in mission-critical applications.

Expertise in Customization & Engineering Support

Custom CNC help

Unlike mass-production CNC shops, we focus on custom, precision-engineered parts for specialized applications. Our engineering team works closely with customers to:

🔹 Optimize designs for manufacturability, reducing costs and improving efficiency.

🔹 Provide material recommendations based on application requirements (e.g., lightweight aluminum for aerospace, corrosion-resistant stainless steel for medical use).

🔹 Offer CAD/CAM programming support, ensuring seamless integration from design to production.

We support various CAD file formats, including STEP, IGES, DWG, and STL, making collaboration smooth and efficient.

Industries We Serve

Customers

Our CNC-machined components are trusted by industries where precision, reliability, and customization are essential:

🚀 Aerospace & Defense – Aircraft components, UAV parts, structural elements.

🚗 Automotive & Motorsports – Engine mounts, brackets, high-performance racing components.

🤖 Robotics & Automation – Precision machined parts for robotic arms, actuators, and automation systems.

🩺 Medical Equipment – Custom surgical tools, enclosures, and prosthetic components.

🏭 Industrial Machinery – High-strength, wear-resistant components for manufacturing equipment.

We adapt to specific industry standards to ensure all components meet required regulations and performance criteria.

Industries We Serve

Quality Assurance & Inspection

Quality Control

At Miradur Precision Machining, we follow strict quality control procedures:

✔ CMM (Coordinate Measuring Machine) inspections to verify dimensional accuracy.

✔ Laser scanning & optical measurement for non-contact precision checks.

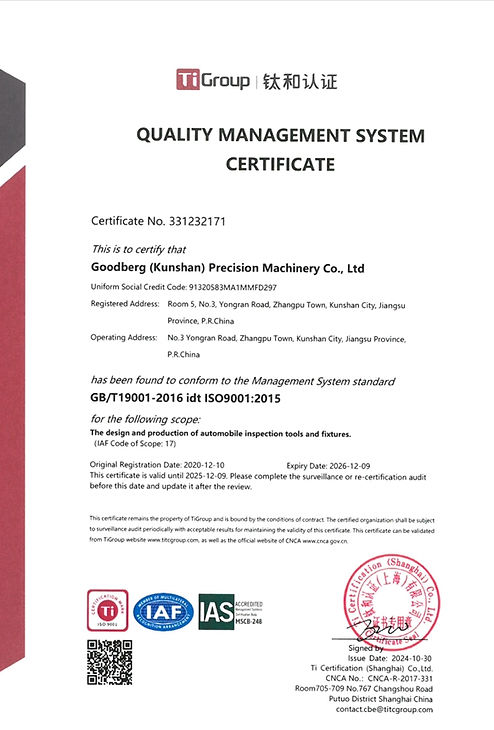

✔ ISO-certified processes, ensuring compliance with international quality standards.

✔ Batch traceability & material certification for consistency and reliability.

Every part undergoes rigorous multi-stage inspections before shipping, ensuring zero defects upon delivery.

Efficient Production & USA Delivery

Logistic

🌎Manufactured in China, Delivered to the USA

We offer fast turnaround times and cost-effective shipping solutions to ensure on-time delivery for U.S. customers.

🚛 Supply Chain & Logistics

-

Flexible production capacity – small-batch, mid-volume, and high-volume orders.

-

Door-to-door shipping with tracking, ensuring safe delivery.

-

Warehousing solutions for bulk orders, optimizing inventory management.

Customers

Miradur Precision Machining - Business Workflow

Our streamlined process ensures high-quality, customized CNC-machined parts with efficient production and delivery to the USA.

Inquiry & Quote

Receive Order

📌 Clients provide design files (STEP, IGES, DWG, etc.), material preferences, and quantity requirements.

📌 Our team reviews specifications and provides a detailed quote with cost, lead time, and shipping options.

CNC

Finishing

🏭 Parts are manufactured using advanced 3-axis, 4-axis, and 5-axis CNC machines.

🏭 High-precision milling, turning, drilling, grinding, and EDM processes are applied.

🏭 Real-time quality checks during production ensure high accuracy and consistency.

Packaging

Delivery

Parts are securely packed for safe international shipping.

📦 Air or sea freight options are available based on customer needs.

📦 Custom clearance & tracking provided for seamless delivery to the USA.

CNC Machining

Production

🛠️ Our engineers analyze the design for manufacturability, cost-efficiency, and performance.

🛠️ Suggestions for material selection and tolerances to meet functional requirements.

🛠️ CAM programming for seamless CNC machining setup.

Finishing & QC

Quality Control

Components undergo surface treatments such as anodizing, powder coating, polishing, and heat treatment.

🔍 Quality control (QC) inspections with CMM (Coordinate Measuring Machine), laser scanning, and hardness testing.

🔍 Each part is checked against tight tolerances before approval for shipment.

After-Sales Support

Service

📞 Customer support available for any questions or modifications.

📞 Ongoing production for bulk or repeat orders.

📞 Continuous improvement to meet evolving customer requirements.

Certifications & Quality Assurance

At Miradur Precision Machining, we meet international quality standards to ensure the highest precision and reliability. Our certifications demonstrate our commitment to excellence:

ISO 9001 Quality Certificate

ISO 9001 Quality Certificate